Friday, September 2, 2011

For ducks, water is more than a nutrient. It is a source of entertainment, a way to keep clean, a method to make eating easier, a way to keep cool in hot weather, an area to mate and a place to find great things to eat. No wonder they spend so much time near water and make such a mess with it!!!

After speaking to hundreds of duck and goose hobbyists and farmers, problems with water is one of their major concerns. "How do I provide it to them in the best way possible and how do I prevent a mess?" It boils down to your drinker/waterer and the flooring around the water source. I will discuss the different types of waterers in another blog. For now, let us look at the best flooring around their water source.

Flooring

No matter the type of waterer you use (bucket, bell waterer, nipples, or automatic float waterer) a slatted or wire floor under the waterer works wonders. The objective is to not allow your ducks and geese to play in their spilled water. This prevents mud from spreading throughout the pen, reduces your bedding bill and keeps the birds and their drinking water cleaner.

After speaking to hundreds of duck and goose hobbyists and farmers, problems with water is one of their major concerns. "How do I provide it to them in the best way possible and how do I prevent a mess?" It boils down to your drinker/waterer and the flooring around the water source. I will discuss the different types of waterers in another blog. For now, let us look at the best flooring around their water source.

Flooring

No matter the type of waterer you use (bucket, bell waterer, nipples, or automatic float waterer) a slatted or wire floor under the waterer works wonders. The objective is to not allow your ducks and geese to play in their spilled water. This prevents mud from spreading throughout the pen, reduces your bedding bill and keeps the birds and their drinking water cleaner.

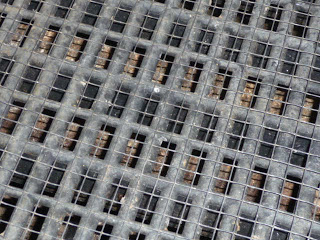

You can use many different types of flooring. You want the openings large enough that the water and manure drop through but you want enough surface area that the birds are comfortable walking on it. In fact, ducks and geese often prefer wire or slat flooring in warm weather as it allows cooler air to circulate below them. The picture above is our breeder ducks on the wire flooring under their nipple waterers. Below is a single flooring piece, 5'x10'.

We have great success with PVC coated welded wire flooring. It is most commonly 1"x1" but we have also used 3/4"x2 1/2" and 1"x2" openings. The PVC coating greatly extends the life of the wire but is more expensive and often difficult to find. You want to get as thick of a wire as possible. Remember that the lower the gauge number, the thicker the wire. The main advantage of welded wire flooring is that there is very little surface area - any spilled water immediately flows through the flooring and out of reach of the duck or goose. The only disadvantage of the welded wire is that it eventually rusts and you must repair or replace it before it injures the feet of your birds. The picture below is the 1/2"x1/2" PVC coated welded wire we use in our smaller brooder room.

There are also many types of plastic flooring made for poultry. Any of these should work well and they typically have a longer life than wire flooring. Below is a 2'x4' plastic poultry flooring piece in use and individually.

For our brooder barn, we purchased a very nice flooring.... for ducklings. Unfortunately the hocks of the geese became caught in the holes from about 3 to 10 days of age. To prevent this we had to put 1/2" hardware cloth over it. This is not good as the manure does not drop through easily and quickly builds up on the floor. But if we only had ducks in there, and no welded wire - it would work great!

Prior to the introduction of plastic flooring, strips of oak were used in the United States. In Asia, strips of bamboo are used. Below is a picture of a hardwood platform and another gray plastic flooring we tried that was originally designed for swine.

Comments

Really Good Blog.

Thank You

sritraders.in

Thank You

sritraders.in

Poultry Feeder, Thursday, November 25, 2021